Every company, whatever its size or sector of activity, is required to take an inventory of its stock at least once a year. In addition to this legal obligation, stocktaking can meet other challenges throughout the supply chain: providing reliable financial indicators, improving overall company performance, improving the accuracy of inventory data, etc. To meet these challenges, a number of stocktaking techniques have been developed: originally manual (using binoculars and paper/pencil, for example), inventory can now be carried out using a barcode scanner, assisted or not by WMS-integrated inventory management software, and more recently, greatly optimized by the emergence of new technologies including RFID, weight sensors, AI solutions, drones, and inventory robots.

In this article, we’ll be focusing specifically on the inventory drone, how it works, its advantages and disadvantages for companies, and the selection criteria that may justify its application.

Inventory drones: What are they?

Contrary to popular belief, a drone is not necessarily a flying device. In reality, it is a flying or ground-based device, without a crew or pilot on board, and whose operation is fully automatic or remote-controlled.

Inventory drones incorporate advanced technologies such as sensors, high-resolution cameras, and sophisticated navigation systems to scan barcodes while navigating their environment. They are designed to optimize and automate inventory processes in various environments. Operating fully autonomously or semi-autonomously with the supervision of a logistics operator, they are equipped with cameras capable of reading barcodes (1D or 2D) or other merchandise identification systems (RFID, artificial intelligence, etc.) allowing them to collect information on stored units, their location or condition. The collected data is then transmitted and analyzed in inventory management or corrected directly in the warehouse management software (WMS).

What are the main uses for an inventory drone?

Inventory drones can be used in various sectors, with storage requirements varying according to the type of material stored. Among these sectors, we will distinguish between indoor and outdoor environments, as well as specific storage modalities for which drone use seems relevant.

Indoor environments:

In warehouses: Inventory drones are particularly well-suited for logistics warehouses as they can perform rapid and accurate inventories of products that are sometimes stored high up or difficult to access. Several storage methods are possible, each with its own characteristics in terms of automating logistics inventory. Logistics warehouses have the advantage of being standardized controlled environments on an international scale, facilitating the deployment of automatic systems (drones or robots).

Agricultural greenhouses: Greenhouses, like warehouses, contain a large quantity of stock in production. Equipped with multispectral cameras and environmental sensors, drones can, for example, detect early water stress, deficiencies, or diseases, optimizing the quality and yield of harvests.

Hangars: Just like warehouses, the use of logistics drones in hangars can enable stocktaking of stored products, by identifying and locating units stored on the ground.

Silos: Equipped with LiDAR sensors or thermal imaging systems, flying or rolling drones can accurately monitor and measure the level of stored materials and the presence of contaminants.

Outdoor environments:

While drones can be used in a multitude of outdoor environments, their use is particularly relevant in certain specific industries.

This is particularly the case for:

- The mining industry: Drones are used to monitor stockpiles of minerals and other bulk materials. They can also be equipped with special sensors to accurately measure the volume of stored materials and provide real-time data on stock levels, create topographic maps, or perform career surveys.

- The agricultural industry: Drones are used to monitor and analyze crops, quickly detecting problems related to diseases, pests, weeds, or water stress.

- The forestry industry: Drones can be used to create precise maps of forests, estimate timber volume, and track tree growth. This information will help forest managers plan and optimize forest harvesting, reforestation, and maintenance activities.

- The automotive industry: Drones can be used to perform precise inspections of factories, warehouses, and vehicle storage yards. This will also allow monitoring the condition of equipment to prevent accidents. In the context of material and vehicle inventory management, drones contribute to the inventory and precise location of spare parts, finished vehicles, and raw materials.

Other industries can greatly benefit from the use of inventory drones. These include the port, oil and gas, recycling and building and construction industries.

Storage methods:

Inventory drones can adapt to a variety of storage methods, including:

- Rack storage: They can easily navigate between aisles and capture HD images of pallets, allowing for precise identification and location.

- Floor storage: The use of drones for floor inventory is possible, but it presents some challenges. Integrated drone lighting or depth sensors are technologies under development to overcome these obstacles.

- Bulk storage (high-volume storage): Bulk storage of products such as metal coils can also benefit from drone inventory. Using 3D image capture, drones can accurately estimate volumes. However, the complexity of some shapes and the variety of materials can limit the effectiveness of this technology.

- Bulk storage (sand, gravel, coal…): Drones will make it possible to accurately measure the volumes and fill levels of silos, hoppers, and storage areas. This information will help managers optimize production planning, prevent stockouts and overstocks, improve material traceability, and reduce the risk of work accidents.

- Tank storage (liquids, petroleum, chemicals): Drones will accurately measure fill levels, detect leaks, and assess the condition of structures (pipes, valves, safety systems) to detect potential damage or maintenance issues. In addition, they improve worker safety by reducing exposure to risks associated with confined spaces, hazardous substances, and heights.

- Stacking (tires, waste): Drones will measure the volumes, dimensions, and positions of stacks, which will ultimately optimize space utilization, improve production planning, prevent stockouts and overstocks. They will also be used to monitor the condition of storage facilities, such as support structures, access roads, and drainage systems.

Advantages and limitations of adopting an inventory drone for use in warehouses with racked goods

Inventory drones offer many benefits to companies, not least in terms of overall improvement in financial and logistical performance, and staff safety. These benefits include:

Time and efficiency savings: drones can scan hundreds of products in just a few minutes (by way of comparison, with traditional methods, an operator scans an average of 1 location every 70 to 90 seconds).

Improving the accuracy of stock data: high-resolution cameras guarantee the reliability of scanned data. Drones also reduce human error (duplicates, omissions, etc.).

Enhanced employee safety: By flying up to several dozen meters, the use of inventory drones eliminates the need for logistics operators to work at heights or in dangerous areas (limiting the risk of falls or work accidents).

Cost reduction: The use of an inventory drone reduces the need for additional human resources, as well as the rental of heavy, expensive equipment (“aerial platforms”, forklift trucks). What’s more, the improved accuracy of inventory data has a direct impact on the company’s operational, and therefore financial, efficiency.

Less downtime: Annual stocktaking often requires several days’ downtime. As a much more efficient alternative to a traditional inventory, the inventory drone drastically reduces downtime (only 1 day’s interruption to scan 25,000 locations with the EYESEE drone). In some cases, when drone operation allows co-activity, no downtime is necessary.

- A deeper understanding of inventory status: The use of inventory drones allows for more frequent inventories, greatly improving the relevance of stock data.

Often perceived as a miracle solution, there are nevertheless several drawbacks that can hinder the adoption of an inventory drone solution, including:

- High initial purchase and maintenance costs: Like many industrial machines, the acquisition cost of a drone can be a barrier for companies with limited budgets or low stock quantities. To these initial costs can be added specialized training depending on the characteristics of the drone and its environment (pilot’s license required or not, indoor or outdoor environment), which requires mobilizing time and human resources. Rental or one-time service solutions can nevertheless be implemented to limit acquisition costs.

- A solution not necessarily suitable for all environments: Depending on the chosen solution, drones may be limited in their ability to evolve in constrained environments (storage height, storage temperature, etc.)

- A solution that requires uniform processes: In order to function optimally, goods must be properly labeled with barcodes or QR codes that are sufficiently readable. When reading is made difficult (brightness, plastic filming, absence of labels, no standards in the naming of packages, irregular placement of labels, etc.), this can greatly hinder the effectiveness of a drone.

Overall, the advantages of inventory drones often outweigh the disadvantages, especially for companies with large warehouses and large inventories. However, it is important for companies to carefully evaluate the costs and benefits before deciding to adopt this technology.

Some criteria for choosing your inventory drone

To choose your inventory drone, it is important to consider different selection criteria.

Warehouse size: The larger the warehouse, the more efficient the drone must be in terms of ease of implementation and speed, and it should not generate significant infrastructure costs (base, codes, beacons, etc.) to cover large distances and complete the inventory within a reasonable timeframe. It is therefore important to choose a drone that can fly for a sufficiently long time without infrastructure and fast enough to cover the entire warehouse within a reasonable timeframe.

Type of identification of logistical units: Inventory drones can be equipped with different types of sensors (barcode readers, Datamatrix, QR codes, RFID, etc.) to identify products. It is therefore important to choose a drone equipped with the type of sensor adapted to the logistical units used in the warehouse.

Possibility of implementing coexistence: The inventory drone must be able to operate safely and without disrupting other warehouse activities for too long, such as order picking or pallet movement.

Type of storage of stored logistical units: Goods stored on the ground, stacked, stored in high racks, one or more deep, or on accumulation racks do not require the same control methods. Some types of storage complicate controls or may require specific sensors or cameras to be properly identified.

Storage height: The drone must be able to access products stored at height, which may require the use of drones equipped with tilting cameras or precise positioning systems to keep the drone at the correct height.

As you can understand, the best inventory drone solution will depend on your environment, your traceability system, and the type of units stored.

The EYESEE inventory drone solution

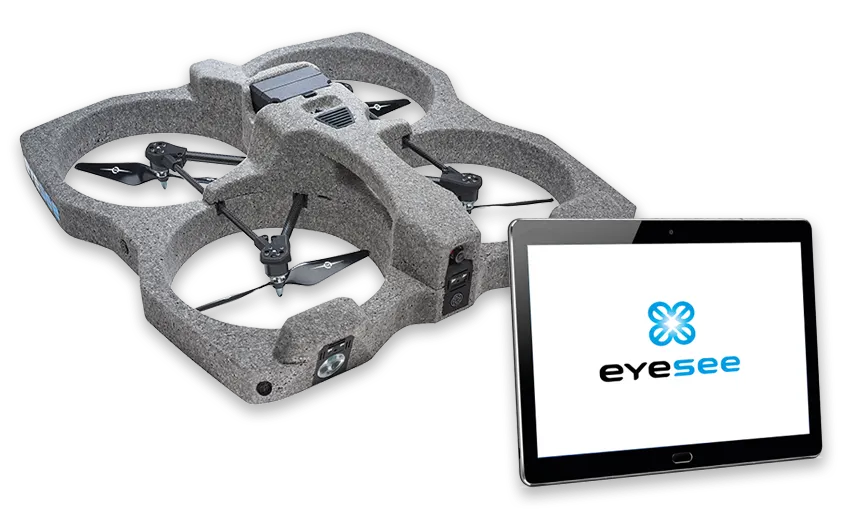

We have chosen to offer a semi-autonomous, lightweight solution that can be easily adapted to pallet racks, without any infrastructure.

What functions does EYESEE offer?

- 1D 2D barcode reading thanks to 3 Zebra scanners located on the front of the drone

- Ultrasonic detection of empty and full pallet spaces

- Automatic flight in a logistics aisle

- Compatible with all WMS

- No need to add or modify warehouse infrastructure

- Obstacle detection

- A powerful, scalable cloud-based system for preparing, planning, executing and analyzing inventory data.

EYESEE in figures :

-

500 locations scanned per hour on average

-

100% reading accuracy thanks to ZEBRA code readers

- 100% co-activity compatible

They’ve switched to EYESEE

L’Oréal: The l’Oréal Cosmétique Active plant adopted EYESEE in 2018. The EYESEE solution has enabled L’Oréal to obtain 100% pallet reading, to switch to cycle count inventory in place of the annual fiscal inventory. The uninterrupted availability of the logistics center has enabled the plant’s production days to be increased, with a return on investment in less than a year. To find out more

GKN: GKN, a world leader in the supply of engineering systems and services, also uses drones for inventory control. Thanks to the use of EYESEE, GKN Driveline has been able to cut its inventory times by 3, reduce associated costs, improve the accuracy of inventory data and reduce the risk of accidents linked to working at height. To find out more

If you would like to know all the benefits of implementing an EYESEE drone, please do not hesitate to contact our teams or fill out the form below directly to test the eligibility of your logistics site.