More and more logisticians are turning to warehouse automation, but which system will suit you best? Let’s start by looking at how you manage your warehouse inventory, and then learn about inventory robot.

Inventory is essential for good warehouse management. It allows to check, identify and evaluate stocks, but also to detect errors or logistic problems such as labeling errors, quantity discrepancies or picking errors.

Imposed by the French commercial code, the inventory must be carried out at least once a year to close the accounting period. There are three types of inventory to be done depending on your needs or your warehouse.

Stock inventory at the end of each accounting period, usually in December

Periodic inventory (several times a year)

Carried out continuously, each time goods are received or dispatched.

There are different types of warehouses depending on the customer’s needs, the goods to be stored or the regulations (outdoor). The largest storage volumes worldwide, which cross from country to country via multimodal platforms, are stored mainly in:

| Production | Storage of raw materials, finished products, packaging material Pallet/ bulk stock |

| Distribution | Intermediate/temporary storage between storage and delivery point |

| Storage/Warehouse | Storage of unsold or end-of-life productse. Pallet |

| Partially open | Rain-sheltered storage with a roof and at least one opened side Rack/Pallet/Bulk |

| Fully open | Open space for storing heavy and large goods. |

| Customs warehouse | Special system for goods before departure for international trade Rack/Pallet/Bulk |

Stock identification must be accurate. An error can lead to high costs and lost time. To ensure optimum inventory management, logisticians are turning to new technologies that ensure better staff safety, save time and reduce inventory errors.

As you can see, the best robot inventory solution depends on the type of inventory, the traceability system and the environment.

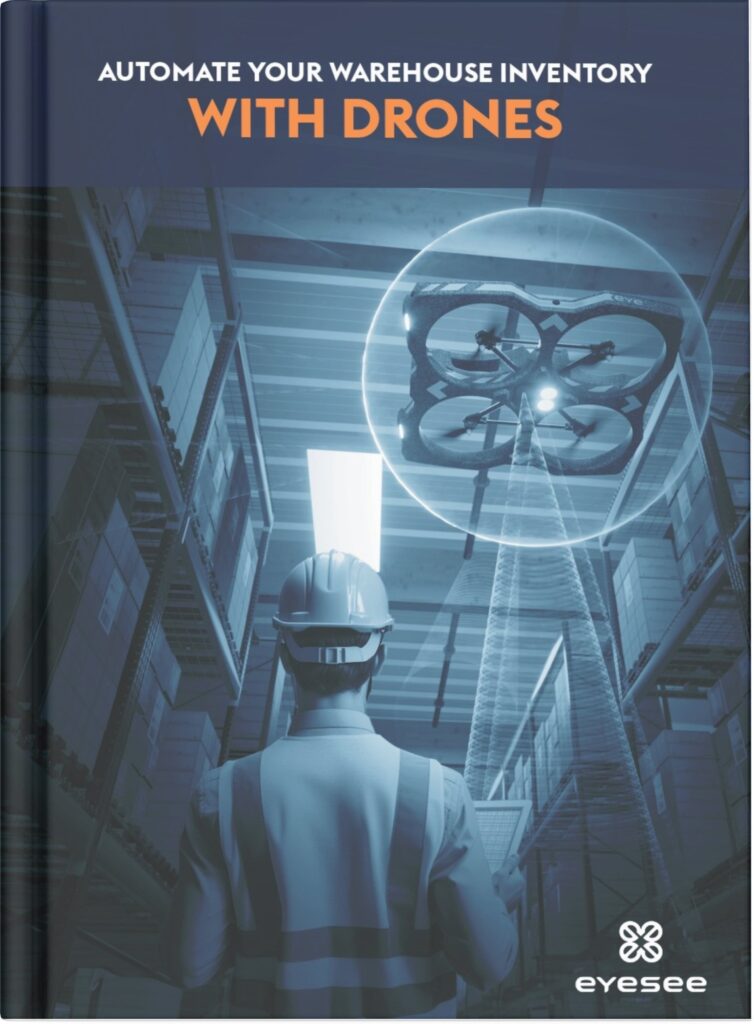

EYESEE chose to offer a semi-autonomous solution, lightweight and easily adaptable to pallet racks WITHOUT INFRASTRUCTURE.

Why choose the EYESEE inventory drone solution?

400 locations / hour on average 100% reading efficiency

Optimization of human, material and financial resources. Can be used in co-activity.

Avoids working at height and the related risks

Reduce the environmental impact of your inventory activities. EYESEE consumes less energy per location visited

automate your warehouse inventory with drones

Multilingual WordPress with WPML