Watch the replay of our first EYESEE TALKS, a round-table webinar dedicated to innovations in logistics and industrial inventory.

In this first episode – “Why we switched to cycle count inventory by drone?” – discover the answers from GKN Automotive and Le Roy Logistique.

Program:

Thanks to our speakers:

If you would like to take part in the next episode of EYESEE TALKS, please contact us 👇

GKN Automotive:

Le Roy Logistique:

As a supply chain manager, you face many challenges on a daily basis: Inventory Shrinkage (IS) is one of them. This phenomenon, which corresponds to the difference between theoretical and actual stock levels, generates considerable financial losses, seriously disrupts your supply chain, and even damages the reputation of your company and your teams. A recent study by the Conseil National de la Sécurité des Magasins revealed that shrink represents almost 1% of French retail sales, or several billion euros each year.

No worries though! EYESEE offers you an innovative solution to take control of your IS and optimize your operations.

IS is a complex problem that spares no industry: from pharmaceuticals to retail, all logistics activities are affected. But what are the causes?

Administrative errors

Damages

Theft

Process-related losses

Forgery

The consequences of inventory shrinkage are manifold and have a direct impact on your business:

Calculating the IS rate is essential to assess the extent of the problem within your company. This metric is calculated as follows:

IS rate = (Registered stock level – Actual stock level) / Registered stock level

By regularly monitoring your IS rate, you can implement corrective actions and measure their effectiveness.

To significantly reduce your SI, it is essential to implement actions targeted at the identified causes:

The EYESEE solution gives you complete visibility of your inventory thanks to:

Ready to boost your inventory management? EYESEE offers you a powerful solution that will enable you to significantly reduce your losses, optimize your supply chain and, consequently, increase your profitability. By offering an enhanced customer experience, you lay the foundations for sustainable growth.

Contact us today to find out how EYESEE can help you optimize your inventory management and boost your competitiveness.

Logistics manager, supply chain manager, logistics analyst… Are you wondering what is the best warehouse equipment for carrying out your high rack inventories: the traditional scissor lifts, or the innovative drones? This is a crucial choice for you, as it has a direct impact on productivity, safety and therefore the cost of stocktaking including indirect costs. At EYESEE, we’ve studied the issue in detail to help you choose the best warehouse automation solution for your business. Let’s take a look at the advantages and disadvantages of each.

Scissor lifts are THE tried and tested solution for accessing high racks in your warehouse. It offers a number of advantages:

However, working with scissor lifts also has its drawbacks:

Welcome to the 21st century! The logistics drone is THE key to the intelligent warehouse of tomorrow. The drone offers a whole host of advantages:

Of course, nothing is perfect! Using drones also has its limitations:

While both solutions have their advantages and disadvantages, how do you make the best choice for your warehouse? It depends on a number of factors that are inherent to your environment:

To help you clarify matters, EYESEE has produced a detailed infographic comparing the advantages and disadvantages of the two solutions.

In conclusion, the drone represents an innovative solution for optimizing your inventories of pallet racks in closed, temperature-controlled warehouses. The scissor lifts remain a relevant solution for certain specific cases. Which solution best meets your needs? Our experts can help you decide.

Would you like to find out more? Contact us now for a personalized study of your needs.

The EYESEE drone inventory solution can now be used in multi-spot mode, ideal for inventory by reference or location samples. Check a selection of locations according to the criteria of your choice in just a few minutes.

When to use the multi-spot feature

3PLs who manage logistics for several customers.

Manufacturers & retailers who need to carry out inventories by reference

If you’d like to find out more about the advantages of using an EYESEE drone, and the use cases for the multi-spot feature, please contact our teams or fill in the form below to test the eligibility of your logistics site.

In this interview, Eric Pierrel, President and co-founder of Darwin Drones the inventory company, tells us about EYESEE’s successes since the beginning of 2023.

Can you tell us more about the first successes since the last fundraising?

“Since the last fundraising, the EYESEE drone inventory solution has been deployed at many customers such as CNHI (Iveco), Aptar, GKN Driveline, or BM Stores…

Our historical customers have also upgraded to the latest version of the solution, such as DB Schenker, Renault Trucks, Le Roy Logistique, Caterpillar…

Our partnership with Hardis Group also continues (events, press, content).

Being part of the global improvement of the operational efficiency of the logistics world also means being visible in the showrooms of consulting companies and for this reason, we have installed two drones at Stratégies & Co (PwC) and Deloitte in Canada”.

What are the priorities and objectives of the EYESEE inventory company for 2023?

“With this latest fundraising, the challenge is to accelerate EYESEE commercially and operationally, both by continuing to serve historical customers to help them benefit from the solution and by supporting new customers in improving their operational efficiency.

In technical terms, the challenges of the coming months are both to improve the drone solution itself, and in particular its reading speed and ease of use. On the other hand, we are investing in the improvement of the Cloud part of the solution to facilitate the analysis of the inventory data collected by the drone via the implementation of dashboards.

Beyond the historical commercial deployment of the solution, we are starting to structure our international approach by identifying local partners for our customers. These include:

IT Genetics in Romania, Checklist Do Brasil in Brazil, Quotes4drones in England.”

What are the dates to remember for this new year?

“This year has started off on a high note with many events.

Like every year, we participated in the SITL (Transport and Logistics Innovation Week).

This year was also marked by the organization of a Roadshow in the AFTRAL centers of France (training centers in transport and logistics). Several demonstrations took place in Grenoble, Moulins, Saint Quentin Fallavier, Chambéry, Valence, Arnas & Montpellier. EYESEE continues its tour of France with several demos scheduled including one on June 20th at AFTRAL Nice.

We will also have the opportunity to present EYESEE at the Modernlog exhibition, on May 30 and 31 in Poznań (Poland) on the stand of our partner Hardis Group Polska.

Other events in France and internationally are planned for the second half of 2023.

Are you planning to implement a CSR approach?

” Yes, for the last few months, we have been working on an analysis of the life cycle of the EYESEE solution versus the traditional solution (inventory with cradles). In this context, we have responded to several calls for projects and we are the winners of the EETE call for projects “Entreprises Engagées pour la Transition Écologique” (Companies Committed to Ecological Transition) supported by ADEME.

We are also laureate of the call for innovative projects of the Club Déméter, dedicated to the development of supply chain solutions integrating CSR issues as well as nominated for the Agora Awards Supply Chain 2023 in the category “Best company of the year in the field of Intralogistics”.

Before the end of the year, we will be able to propose a detailed report on the environmental gains offered by the EYESEE solution with precise data and field analysis.

EYESEE is delighted to have participated in the Vertical Forum 2023 at the Swiss Aeropôle in Payerne. On this occasion, many companies were present to discuss the professional use of drones (logistics, construction, agriculture, security, audiovisual, civil engineering, urbanism & real estate).

Thanks to Stanley Schmitt, director of Vertical Master (Training and Consulting) for the opportunity.

The objective of Vertical Forum is to create a meeting place between manufacturers, operators and regulators of all types of drones through presentations and demos.

The 2023 edition was very successful with a good audience, the presence of Swiss media (RTS) and especially drone actors from the three linguistic regions of the country.

“Vertical Master had been planning for several months to explore the segment of drone use in logistics. This segment is not yet well known by drone players who are more on inspection or mapping. EYESEE Inventory Drone, with its very innovative solution, seemed to us to be the ideal candidate to enter the logistics world” explains Stanley Schmitt.

Clément Roulet Dubonnet – Marketing Director EYESEE

What are the future synergies with Vertical Master?

Vertical Master could offer a global solution to Swiss customers interested in integrating drones in their inventories. This global solution could include the equipment but also the complete integration of the solution with training and after sales service. Note that Vertical Master would also be able to bring its drone expertise in national languages (French, German and Italian). To be continued…

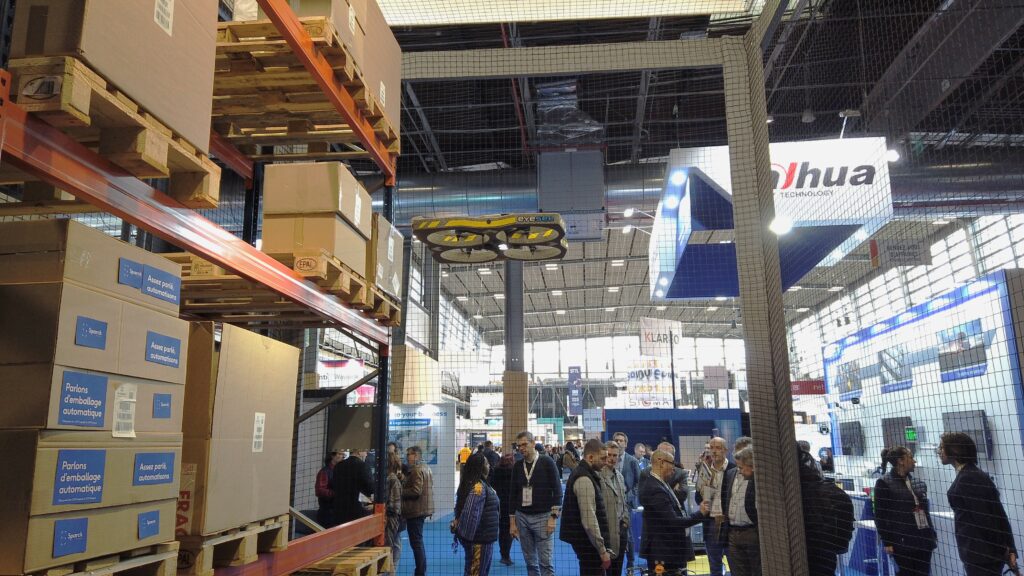

EYESEE exhibited its latest innovations in warehouse technology at the 40th edition of the Transport and Logistics Innovation Week (SITL), which took place from March 28 to 30 at the Porte de Versailles in Paris.

SITL has become one of the main events for transport and logistics professionals. The international trade show, which is celebrating its 40th edition this year, brings together all supply chain players from sectors as diverse as intralogistics, robotics, IT systems and logistics real estate. The 2023 edition gathered more than 24,000 participants and 500 exhibitors.

For this 40th edition, the inventory by drone was in the spotlight on our booth D113.

On this occasion, participants were able to see the drone in flight in the Drone Valley and discuss with our team.

EYESEE is a solution designed to help manufacturers and logisticians increase their operational efficiency. It allows to carry out the inventory by collecting automatically the data of stocks of the warehouses. The solution can be deployed in a few days, without any modification of the warehouse or addition of infrastructure.

With an average productivity of 400 locations/hour, EYESEE allows you to increase the reliability of your inventory data while reducing the risks on your site.

The drone inventory solution complies with all current industry standards. It helps 3PLs and logistics departments of manufacturers to eliminate inventory errors before they become downstream problems. L’Oréal, Bayer, GKN Driveline, Le Roy Logistique, Ikea, Aptar and many others have already chosen EYESEE.

Interested in deploying the EYESEE solution in your warehouse?

Check the eligibility of your site by clicking on the button 👇

A question about the features of the logistic drone, its autonomy or its advantages? We answer all your questions in this article

The solution is adapted to each type of warehouse:

The logistic drone can be used in warehouses along the value chain (raw material warehouses, production sites, finished goods warehouses). All you need is a palletized warehouse.

Among our customers who have deployed the solution in Europe

No, the logistic drone EYESEE does not count stocks (the number of goods on a pallet). This drone is designed to ideally read the HU tags (barcodes on full pallets filmed in the Handling Unit). It provides accurate stock data with photos and thus allows to detect empty pallets, obstacles and to anticipate position errors beforehand.

It depends on the type of inventory you adopt and the frequency you use the solution. Another important factor is the size of your warehouse. The EYESEE solution can read an average of 400 locations per hour and the battery pack provided allows for about 2 hours of flight time. The calculation is simple :). Depending on the warehouse and the size of the locations, the efficiency can reach 800 locations per hour.

No, EYESEE is a solution that requires the presence of an operator to supervise the flight of the drone. However, the operator does not need to be trained to fly the drone or to use joysticks. Simply pressing the buttons on the application is enough. During an inventory mission, the drone operator makes sure that the flight is going well, and can also report problems on the tablet application (points of interest related to the goods, the pallet or the rack for example).

When the logistic drone finishes its inventory mission (one side of an aisle) it lands and touches down. The operator must also change the battery when necessary and move the drone to the next aisle.

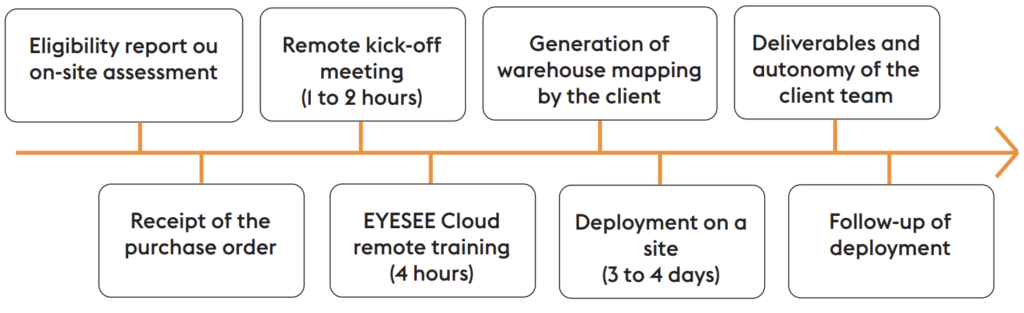

It’s quick. There are a total of 3 training sessions: 2 short sessions of training on EYESEE Cloud remotely and 2 to 3 days of training on the use of the drone on site (most frequently when the equipment is delivered). It is not necessary to have a telepilot license.

These sessions are spread over a typical period of 12 weeks from the date of order (can be accelerated depending on stock availability).

Important point: no infrastructure or addition of codes or labels for localization is required.

Grenoble, France, December 8, 2022 – The startup Darwin Drones, which develops and markets the Eyesee drone inventory count, announces a €1 million round of funding, bringing in the Groupe Idec through its investment subsidiary Team Invest Innovation, the Crédit Agricole Alpes Développement, as well as several business angels.

The startup now has the necessary means for the commercial deployment of Eyesee to logistics and industrial sites in France and abroad. After having attracted first customers such as L’Oréal, Bayer, DB Schenker, and Leroy Logistique, who adopted the Eyesee offer since its prototype stage, Darwin Drones is now aiming to set up a network of distributors and integrators in its main target markets.

“This fundraising, following an initial market validation, confirms the relevance of Eyesee’s positioning to automate and make the inventory processes of industrial and logistic sites more reliable. We are delighted to welcome new shareholders who are commited to our side. This funding allows us to start our acceleration and internationalization phase with serenity and determination.”, comments Eric Pierrel, president of Darwin Drones.

Eyesee was born in 2015 from a Grenoble-based collaboration combining the logistics DNA of Hardis Group and the industrial drone expertise of Squadrone System. It was therefore quite obvious for Darwin Drones to approach investors active in the Grenoble area, in particular Crédit Agricole Alpes Développement and Grenoble Angels.

“The Eyesee project, led by Darwin Drones, showcases Grenoble’s technological and commercial expertise on a national level and is now beginning its international journey. We are delighted to be able to support this project and especially the management team, which combines an ability to listen with notable responsiveness and dynamism.“, explains Rami Hassoun, equity investor at Crédit Agricole Alpes Développement.

“For us, supporting such a project means that we believe in the strong development potential of the Eyesee inventory drone solution dedicated to stocktaking within logistics sites using an autonomous drone. Eyesee has been proven for more than 5 years with many customers already using it, demonstrating impressive results compared to traditional stocktaking methods. Darwin Drones is determined to deploy this disruptive solution on a larger scale in France and internationally for the logistics sector, which is always on the lookout for innovative and reliable solutions to improve productivity. Finally, Eyesee was created and developed in the Grenoble area by experts in logistics and drone engineering, it was thus important to support this project in its commercial launch phase.”, explains Jean-Yves Costa, the project’s instructor and investor at Grenoble Angels.

The development of partnerships being a strong vector for growth for Darwin Drones, the recent fundraising is also an opportunity to create synergies. Thus, the Groupe Idec, a major player in real estate and construction, which operates as a planner and developer, investor, turnkey designer-builder, and creator of energy solutions, is joining the Eyesee project to accelerate its market access.

“Our stake in Eyesee is the result of a global approach to the need for tools that promote the development of industry and logistics 4.0“, comments Patrice Lafargue, President of Groupe Idec. “We are thrilled to partner with the Darwin Drones team and its other shareholders to develop this project, which combines an innovative vision and a pragmatic approach to strengthen the digitalization of logistics platforms. We have an incredible portfolio of projects with some 700,000 m2 of warehouses that we build each year and the nearly 1,700,000 m2 of buildable space throughout France to give this innovative solution a tremendous boost.”

Thanks to the press!

Founded in 2021, Darwin Drones is specialized in the development and marketing of industrial logistics automation solutions, especially by drone. Darwin Drones also provides services associated with this activity. The company is dedicated to the sales, support and software development of the Eyesee solution for the logistics market.

Press contact: Nora NESSER – +33(0)6.43.53.64.01 – nora.nesser@eyesee-drone.com

C2AD is the private equity vehicle of Crédit Agricole Sud Rhône-Alpes and Crédit Agricole des Savoie. Crédit Agricole Alpes Développement is involved in venture capital, innovation capital, development capital and transmission capital (startup, SME and ETI). C2AD manages €100 million, invested in 180 companies.

Press contact: Rami HASSOUN, – equity investor – rami.hassoun@ca-alpes-developpement.fr

Groupe Idec is a major player in the real estate sector, bringing together more than twenty companies with expertise in their fields. It operates in France and abroad to plan, develop, finance

and provide innovative energy solutions, as well as to design and construct all types of buildings.

It positions itself as a responsible player in the energy transition and in limiting the artificialization of land. The company works with local authorities on each new operation to revitalize territories by creating new living and working spaces. This commitment translates into a desire to contribute to the green growth of cities, businesses and individuals, while meeting the challenges of

sustainable, coherent and pragmatic economic development.

Key figures:

▪ Year of creation: 2000

▪ 500 employees in France + 700 worldwide

▪ 500 million euros of Revenues

▪ 3 million m2 certified

▪ 20 companies in France

▪ + 1,000 Ha developed or in progress in France and internationally

▪ 260,000,000 euros of assets

▪ 700,000 m2 built each year

▪ + 20 logistics parks in France and abroad.

Press contact for Groupe Idec : Isabelle BIGOT – 06.16.06.91.23 – isabelle@calliope- event.com

Created in 2005, Grenoble Angels is an association affiliated with France Angels, the national federation of business angels. Grenoble Angels brings together a hundred local investors throughout the Isère department, who support and finance start-ups and innovative companies in their seed phase.

With more than 15 years of experience and over 200 projects funded, Grenoble Angels relies on the experience and expertise of its members to support local entrepreneurs and projects.

Grenoble Angels’ philosophy is based on the 3 C’s: the triple contribution of Business Angels in Capital, Competencies and Contacts.

Key figures since 2005:

-More than 1,000 investment opportunities investigated § 250 companies funded

-25 million euros invested by Business Angels

-200 applications received per year

-10 startups supported and funded every year

Follow Grenoble Angels:

Website: https://www.grenoble-angels.com/

LinkedIn: https://www.linkedin.com/company/grenobleangels

Twitter: https://twitter.com/grenobleangels

Press contact: Jonathan COLLOMB – délégué général- 04 76 28 25 32 – contact@grenoble- angels.com

Watch the replay of our webinar and learn how drone inventory count allows you to increase productivity in your warehouse.

Program:

Using new technologies for inventory automation, and in specific the drone inventory count, allows to improve the production.

Inventory drone offers many advantages to companies, as explained in this webinar by Clément Roulet Dubonnet, co-founder of Darwin Drones.

Darwin Drones is the company dedicated to the marketing, support and software development of the EYESEE drone inventory solution for the logistics market.

Inventory and stock keeping activities are time-consuming and inefficient but simple. Yet production depends on the quality and efficiency of this process.

EYESEE simplifies these activities to have a more accurate inventory and a more fluid activity at any moment.

Why are finished goods warehouses switching to EYESEE?

With drone inventory count EYESEE, you can :

Multilingual WordPress with WPML