The digitization of the supply chain is progressing apace, and automation technologies are now finding their way into even the historically tedious tasks of stocktaking.

Among the most promising innovations: inventory drones. This means shorter inventory times, more accurate data and tangible safety benefits for logistics operators.

But can these automated tools replace traditional counting methods? What kind of performance can we really expect from them? Can they really count parcels? We take a look at their real capabilities: can an inventory drone count ?

What are inventory drones made of? What is their main functionality?

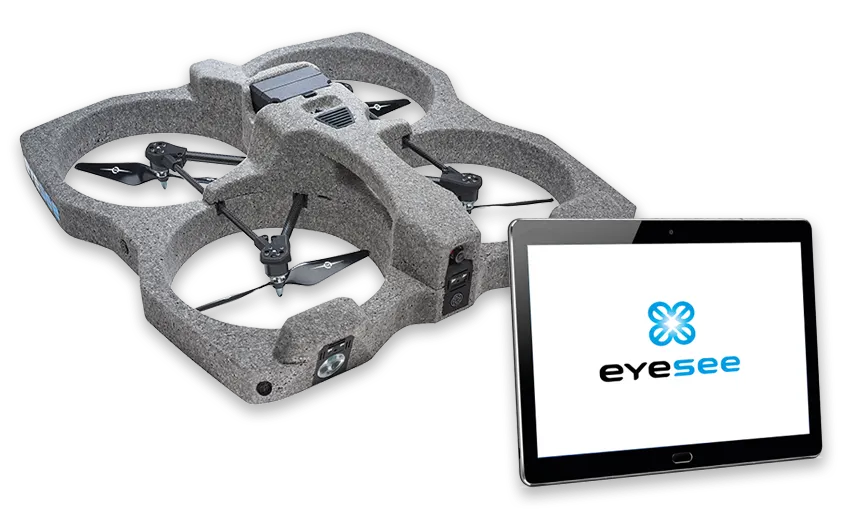

Before discussing the capabilities of inventory drones, it’s important to understand what technologies they carry. In fact, they incorporate a whole range of advanced components to enable them to carry out complex tasks, and can be equipped (depending on the model) with :

- latest-generation sensors,

- barcode or QR code readers,

- high-resolution cameras,

- computer vision modules,

- LIDAR (Light Detection and Ranging) technology,

- autonomous navigation systems.

These technologies will enable them to move autonomously or semi-autonomously in

warehouses, map spaces and locate items with great precision.

Their main function is to scan and identify barcodes or other visible data

(description, quantity, reference) to update the WMS or validate inventory operations.

What are the right conditions for successful identification?

Today’s drone inventory technologies are increasingly mature, enabling labels on cartons to be identified efficiently, provided certain conditions are met:

- Labels in direct view (less reliable at the bottom of pallets or behind other cartons),

- Clear, legible and standardized labelling,

- Structured, regular arrangement of packages.

On the other hand, several factors degrade performance:

- Bulk or disorganized environments,

- Lack of labeling or non-standardized labels,

- Presence of opaque plastic films or light reflections.

Can you really count the boxes on a pallet with a drone?

As things stand, the answer is no. No solution is really capable of accurately “counting” the number of cartons on a pallet.

What these tools actually do:

- Detection of presence at a given location

- Front label reading

- Estimation of the number of cartons visible on a face

- Inference of total volume, based on assumed depth

For example, if 9 cartons are visible from the front, the system can assume 3 similar rows behind (it will infer that there are 27 cartons on the pallet). But this visual inference is imprecise and not equivalent to a real count, especially from an accounting point of view.

Limits of visual inference in automated counting :

Some advanced systems can estimate the volume or size of packages based on :

- object recognition,

- stack density,

- or comparison with historical data.

However, although this approach can be used for rapid control, it does involve a significant margin of error, particularly when packages are stacked irregularly or their shape or visibility is partially obstructed.

⚠️ As a result, the inference does not allow reliable counting for annual inventory or cycle counting.

Inventory drones, a powerful lever for reliability…provided you’re well prepared.

As you may have read in this article, drones are ideal tools for detecting the presence of packages, retrieving information from labels, and making inventory operations secure and reliable. Today, however, they are incapable of accurate counting, altho