The EYESEE drone warehouse project became the laureate of the call for projects “Entreprises Engagées pour la Transition Ecologique” (Companies Engaged in the Ecological Transition) and was supported by the ADEME.

ADEME (French Environment and Energy Management Agency) is an expert agency that meets the challenges of ecological transition, in order to build a sustainable future in a low-carbon world.

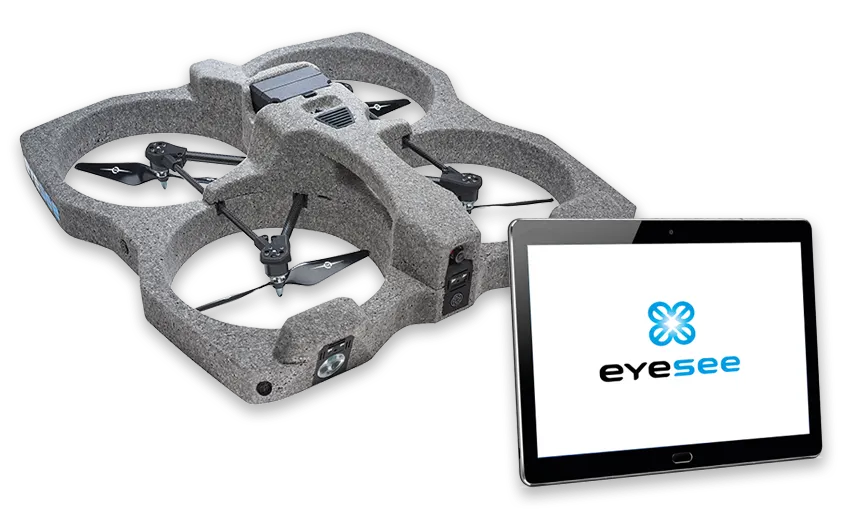

EYESEE has participated in this call for projects by presenting the automatic drone inventory solution and its benefits in terms of reducing the negative impacts generated by using manual inventory. In fact, the drone inventory solution for logistics warehouses significantly reduces the environmental impact of warehousing activities while providing economic benefits. Extensive studies are currently being carried out to precisely quantify the differences.

The inventory mobilizes a lot of resources and has a negative impact on the environment. The standard manual process, i.e., the use of scissors lifts and scanners, is a low-value-added activity that poses safety (working at heights), quality and reliability problems due to human error. It requires the transport of scissors lifts (often rented, sometimes managed internally) to the logistic site and this causes a high environmental impact due to the transport of scissors lifts by truck (from 2 to 4 tons per scissors lifts).

Inventory is resource intensive and has a negative impact on the environment. The standard manual process, i.e., using cradles and scanners, is a low-value-added activity, with safety (working at heights), quality and reliability issues due to human error. It requires to bring on site platforms (often rented, sometimes controlled internally) and it has a high environmental impact due to the transport of these platforms by truck (from 2 to 4 tons per platform).

VS

The use of EYESEE inventory robot therefore eliminates the use and trucking of scissors lifts for inventory activities by using a drone to collect data. Moreover the energy consumption per location visited is 10 times lower with a drone than with a scissors lifts.

For these reasons and many others, EYESEE drone warehouse is the laureate of the EETE (Companies Committed to the Ecological Transition) call for proposals, which consists in supporting the international diffusion of the progress brought by this modern and economical method of carrying out inventories in a rack.